BCS-460 Control Panel

Moderator: Post Moderators

BCS-460 Control Panel

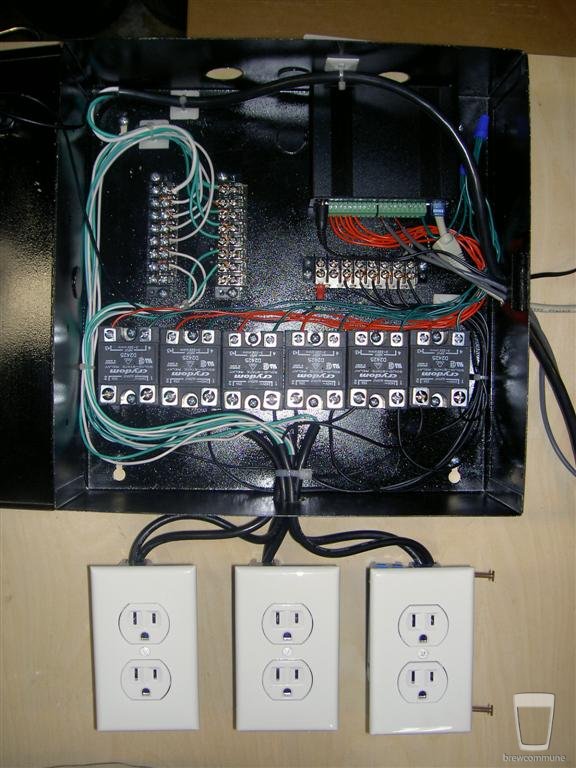

For those interested in this kind of thing, I finished up wiring my control panel (the BCS-460 from http://www.embeddedcontrolconcepts.com) for the automated controller yesterday. It is working great. Now I just need to finish up changing around the gas line. Each outlet will control a separate gas valve or a pump.

- backyard brewer

- Posts: 3774

- Joined: Fri Feb 18, 2005 5:38 pm

- Location: Orange County, CA

- Contact:

Re: BCS-460 Control Panel

Very nice work!

I gotta get mine working too.

I gotta get mine working too.

Re: BCS-460 Control Panel

It's only available internally, however, on the embeddedcontrolconcepts.com site there is an actual demo controller available for access.jward wrote:Very cool. What's it's IP address?

Re: BCS-460 Control Panel

ECC Wiki wrote:Connect to the unit by opening a web browser window and entering in the target IP address of the controller. Currently Firefox, Safari, and Chrome browsers are supported. Internet Explorer is currently not supported. Firefox is recommended.

Funny to see this. So many apps require winders or exploder.

- backyard brewer

- Posts: 3774

- Joined: Fri Feb 18, 2005 5:38 pm

- Location: Orange County, CA

- Contact:

Re: BCS-460 Control Panel

Just in case anyone is wondering, this is what the control panel of the BCS460 looks like:

and since it's an embedded web server, if you have a static IP address you can control your system from anywhere you have a browser. Not very useful for brewing but kinda cool for fermentation...

and since it's an embedded web server, if you have a static IP address you can control your system from anywhere you have a browser. Not very useful for brewing but kinda cool for fermentation...

- backyard brewer

- Posts: 3774

- Joined: Fri Feb 18, 2005 5:38 pm

- Location: Orange County, CA

- Contact:

Re: BCS-460 Control Panel

I guess you don't need to heat sink the SSR's since they're only switching light loads? Any concern with switching the inductive load of the pump?

Re: BCS-460 Control Panel

ECC should have a beer XML parser to read and set up the programming for the mash and sparge included in a recipe.

Re: BCS-460 Control Panel

That was the conclusion I came to after researching it. They are mounted in a metal enclosure, and based on the light loads I'm driving, it sounds as the metal enclosure should help to dissipate the heat. If I was driving electric elements, then it sounds like that is a whole other story and you would want a heat sink. I'll watch it when I do the water tests, which will hopefully be this weekend.backyard brewer wrote:I guess you don't need to heat sink the SSR's since they're only switching light loads?

I'm not too concerned about it as the pumps aren't really heavy draws, but maybe I'll be telling another story in a couple more weeks. We shall see. I should know more soon. This is a little bit of trial and error for me as some of this (mainly the electrical side) is new stuff for me, so if there are any ideas to improve it, I'd love to hear them. I'm also documenting some of it on my blog to hopefully help someone else out in the future.backyard brewer wrote:Any concern with switching the inductive load of the pump?

- backyard brewer

- Posts: 3774

- Joined: Fri Feb 18, 2005 5:38 pm

- Location: Orange County, CA

- Contact:

Re: BCS-460 Control Panel

I'm waiting to see how they work for you, lol... What was the word on the cheaper Chinese SSR's? I seem to remember that they leaked a lot of voltage?

I read some info that said don't use an SSR with an inductive load and others that said just reduce the usable current by 50-70% Those Crydom units look like they're pretty high quality so I imagine you'll be just fine.

I think I'm going to add a RIMS tube to my new system so I'll need to heat sink one pretty well. I have some P4 heat sinks with fans that I'll use.

I read some info that said don't use an SSR with an inductive load and others that said just reduce the usable current by 50-70% Those Crydom units look like they're pretty high quality so I imagine you'll be just fine.

I think I'm going to add a RIMS tube to my new system so I'll need to heat sink one pretty well. I have some P4 heat sinks with fans that I'll use.

Re: BCS-460 Control Panel

You are more than welcome to experiment with anything I have! On the other SSR's, I looked into them, but being the Crydom's seemed highly recommended on the ECC forums and I found them for $10 a piece on eBay, I opted for the Crydom's.backyard brewer wrote:I'm waiting to see how they work for you, lol... What was the word on the cheaper Chinese SSR's? I seem to remember that they leaked a lot of voltage?

I read some info that said don't use an SSR with an inductive load and others that said just reduce the usable current by 50-70% Those Crydom units look like they're pretty high quality so I imagine you'll be just fine.

I think I'm going to add a RIMS tube to my new system so I'll need to heat sink one pretty well. I have some P4 heat sinks with fans that I'll use.

Re: BCS-460 Control Panel

What's the skinney on an SSR vs. OR (ordinary relay  )? Why not an ordinary relay?

)? Why not an ordinary relay?

- backyard brewer

- Posts: 3774

- Joined: Fri Feb 18, 2005 5:38 pm

- Location: Orange County, CA

- Contact:

Re: BCS-460 Control Panel

SSR's have no physical contact, so nothing wears out. They also react much much faster, so you can use PWM to control a resistive load lile a heating element. So, they are fast enough that using PWM you could control a heating element at say 50% output. A mechanical relay cannot act fast enough for that kind of control. Because of that they work much better with PID logic as well. They can be triggered with TTL level control of only 3-5V and less than 20mA. A physical relay usually requires a lot more current and therefore has to have a transistor driver. If that weren't reason enough, they can handle 25A if they are properly heatsinked.jward wrote:What's the skinney on an SSR vs. OR (ordinary relay)? Why not an ordinary relay?

The downsides are that they tend to leak some voltage and the cheaper ones can only drive AC loads. Niether of which is a problem for our application.

Become a Brewer's Hardware Fan on Facebook!

Become a Brewer's Hardware Fan on Facebook!